GE Aviation and their software partner Upskill are seeing success by giving their mechanics smart tools and smart glasses, the latter in the form of Google Glass.

In a pilot program at their Cincinnati factory, GE Aviation gave a team of mechanics Google Glass Enterprise Edition and Upskill's Skylight software to assist them in assembly and maintenance of aircraft engines. Skylight provides hands-free instructions, in the form of process flows, images, videos, and animations, via the Glass display as well as video sharing with remote support teams.

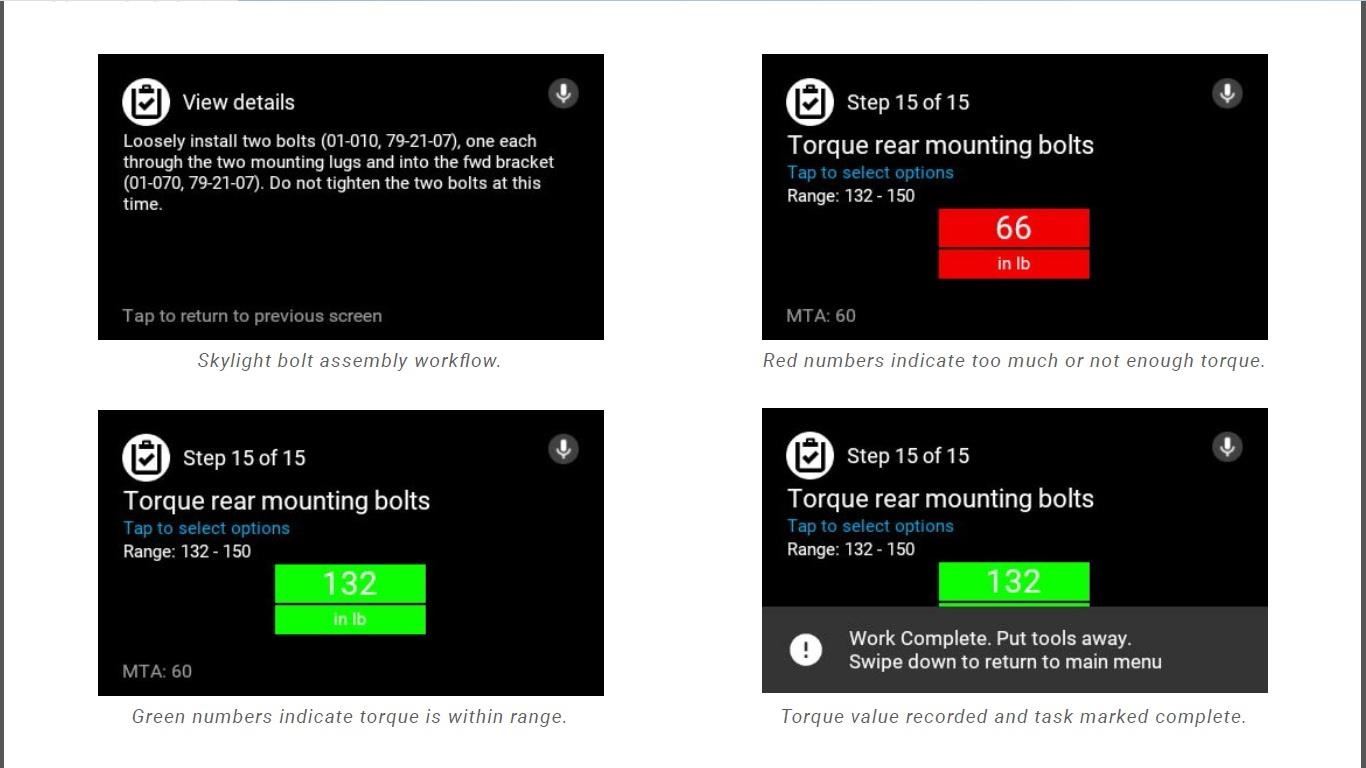

Certain steps of the process specify that nuts are screwed on with the appropriate amount of force, requiring a torque wrench. To improve this process, GE Aviation equipped the mechanics with WiFi-enabled torque wrenches.

Skylight notifies the mechanics when the wrench is needed. The software then communicates with the wrench to measure the amount of force applied, displaying the measurement on the Glass display. Skylight also records the torque measurement, creating an audit trail for future reference.

This has tremendous potential to minimize errors, cut down on costs and improve product quality. We've also seen an increase in productivity and efficiency improvements.

While GE estimates that the technology could save the company millions in costs over a ten-year span, early reports from their workers are positive as well, with 85 percent of pilot participants admitting that the system would reduce errors.

A video demonstration illustrates how much more efficient the process is with augmented reality. A senior mechanic is able to complete his task 16 percent quicker when he does not have to continually refer to a job guide for instructions or confirm of the amount of torque required.

GE has applied Skylight to seven projects at 12 locations across various business units. The company cast their vote of confidence in the technology earlier this year, when their GE Ventures unit joined their counterparts at Boeing HorizonX in a in a Series B round of funding in Upskill.

Last month's announcement of Google Glass Enterprise Edition took many by surprise, in part because their customers and software partners had to follow Fight Club rules. As Wired reported, Google asked that their early enterprise customers not talk about the Enterprise Edition. Now that the veil of secrecy has been lifted, expect more companies to tell their stories.

Just updated your iPhone? You'll find new features for Podcasts, News, Books, and TV, as well as important security improvements and fresh wallpapers. Find out what's new and changed on your iPhone with the iOS 17.5 update.

Be the First to Comment

Share Your Thoughts